CUSTOM-MADE STAINLESS STEEL Channels FROM PURUS FOR THE INNOVATION CENTER

Real estate company Fabege is responsible for the development of the property Separatorn 1, part of the urban development in the Stockholm South Business District in Flemingsberg. Alfa Laval becomes the first major tenant with offices and an innovation center accommodating everything from separators to clean ballast water.

Flemingsberg in Huddinge is one of Stockholm’s most expansive areas with plans for many new residences and offices. Fabege is a key player on-site, planning and developing new and attractive spaces for several major entities, including the Opera/Drama Theatre and Alfa Laval.

The goal is to create an attractive hub for business south of the city center, with around 50,000 working individuals and residential environments for 50,000 residents. Here, they can take advantage of the collective and regional transportation hub and one of Stockholm’s largest nature reserves.

TWELVE FLOOR PLANS FOR INNOVATIVE WORK

The construction of Separatorn’s twelve floors began in the summer of 2022, with planned occupancy in the spring of 2025. The new workplace for Alfa Laval and their innovation center for ‘high-speed separation and emerging technologies’ aims to enable new ways of working with a high-tech laboratory for product development and testing. The property will also feature a restaurant, parking garage, and various technical spaces.

The project has taken shape with the involvement of, among others, Brunnberg & Forshed (house architects), Tham Videgård (external design), and Wingårds (interior design). Fabege is committed to minimizing the building’s carbon footprint over its lifespan by using renewable energy sources and a high level of energy recovery. The goal is to achieve certification for the building at the Excellent level according to BREEAM-SE standards

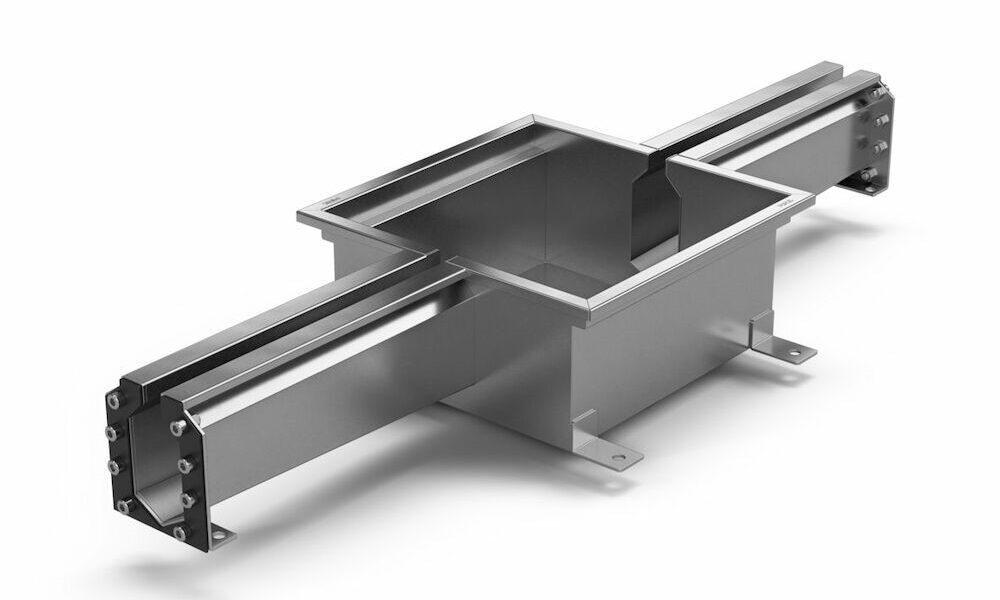

CUSTOM-MADE PURUS DRAINS SOLVED CHALLENGE WITH LOW BUILDING HEIGHT

Mälarrör Installation AB is responsible for the plumbing installations in the project. They turned to us at Purus for advice and to discuss details regarding the choice of solutions for drainage systems on different floors. One challenge arose on the 3rd floor, which had such a low building height that they didn’t believe there was a ready-made solution with stainless steel floor drains that could be used. They were considering a solution with a cast-in-place form directly in the floor, followed by complementing it with Purus grates.

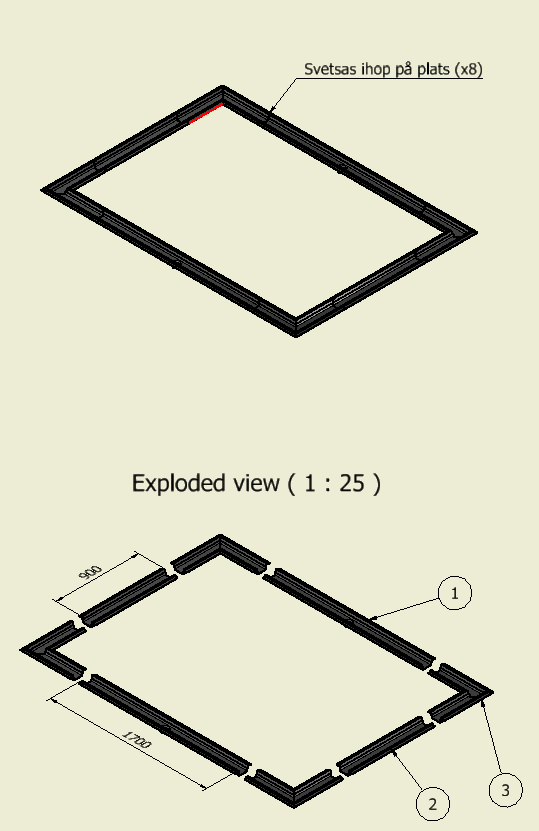

Our drain specialists proposed a different solution, suggesting that we manufacture the lowest possible height for our Purus drain slot module for mass floors, without slope and without flange joints, which they could then weld together on-site.

This way, they could have drains that worked for the entire floor, avoiding the need for custom casting the floor. It was a more efficient and secure solution that they quickly accepted.

” PURUS HAS BEEN VERY HELPFUL IN THE WORK OF FINDING THE SOLUTION THAT WAS BEST SUITED FOR THIS PROJECT'S NEEDS. WE HAVE HAD A GOOD DIALOGUE ALL THE WAY AND LOOK FORWARD TO VISITING THEIR PRODUCTION FACILITY IN SMÅLANDSSTENAR TO SEE HOW THE DRAINS ARE MANUFACTURED."

John Norling, Responsible for Bids and Estimates at Mälarrör AB

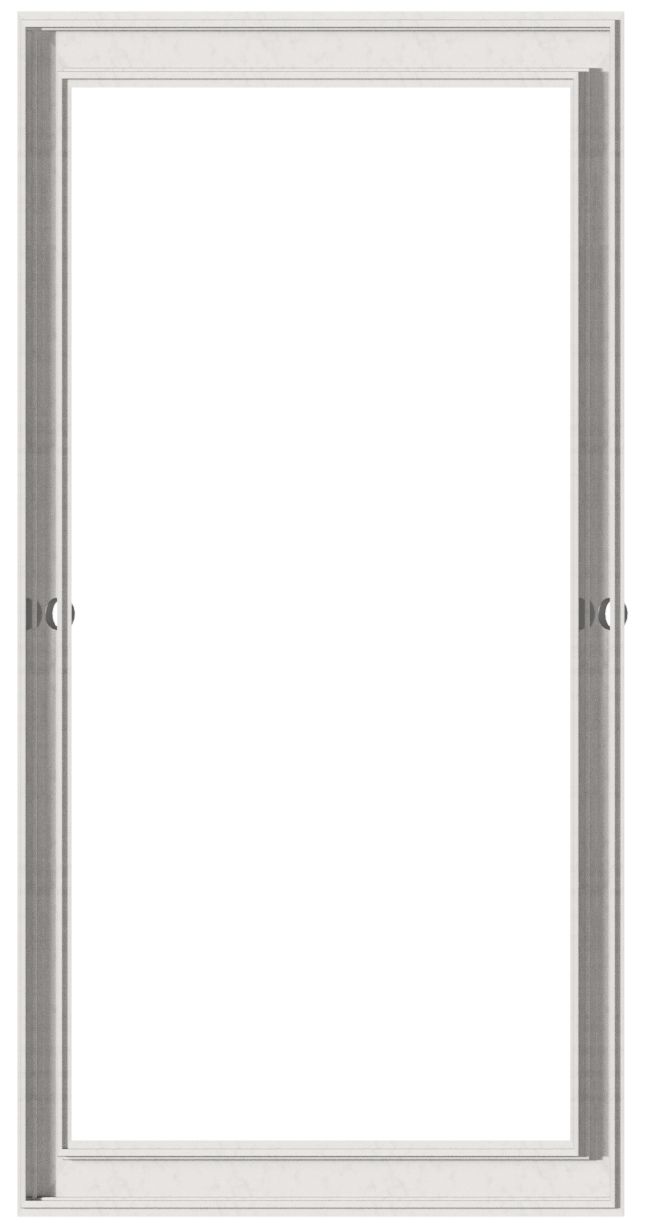

In total, Purus is supplying 788 meters of floor drains and drains to floors 1–4, which include a restaurant, garage, changing rooms, technical areas, bike room, entrance, innovation center, conference, and office spaces.

The selected products include customized models in the Purus drain slot module system, as well as Purus drain 100 for mass, along with about 30 stainless steel drains for the base plate, modified for application in asphalt.

Feel free to contact me if you have any questions about the solution or if you are interested in advice for a similar project!

Niklas Jönsson

niklas.jonsson@purus.se

+46 70 265 80 18

Purus channel spalt modul & Purus channel 100